How DMI’s 6-Phase Process Can Help Ensure NPI Success With so many steps to consider, introducing a...

New Product Introduction Can Take Many Shapes

A Flexible NPI Mindset Allows for Nimble Changes

NPI is generally associated with the design and manufacture of a tangible product, but when you are in the service industry, it can be a new capability that you are able to offer to your customer base. Sometimes, activity on NPI can be a well-planned and executed design process, and other times it can happen as a result of a new customer need. That is the case for us at Diversified Machining.

We have a long-term customer relationship with a company that does injection molding. Over the years, they have been sourcing their molds from a local mold maker, and our shop has been called on to make minor modifications on the molds as needed, but we were never considered for the actual manufacture of the mold itself. Recently their relationship with their mold maker has changed, and they asked us if we could provide the turnkey molds, to their design. This is an opportunity for a new revenue stream, and could be offered to multiple customers once acquired. We certainly have the machining expertise to make the molds, so what else did we need, to be able to offer this new service?

molds from a local mold maker, and our shop has been called on to make minor modifications on the molds as needed, but we were never considered for the actual manufacture of the mold itself. Recently their relationship with their mold maker has changed, and they asked us if we could provide the turnkey molds, to their design. This is an opportunity for a new revenue stream, and could be offered to multiple customers once acquired. We certainly have the machining expertise to make the molds, so what else did we need, to be able to offer this new service?

The Prelim Review

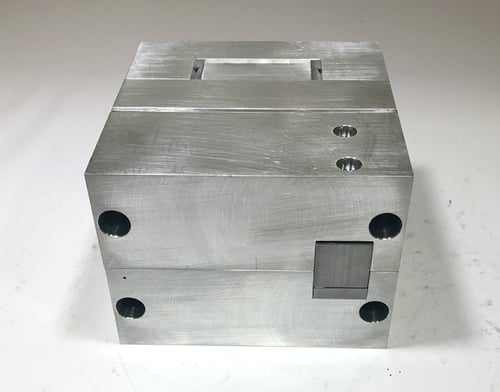

The customer provided us with three drawings of new molds they needed made—for us to review and to quote on, if possible. Two of the molds were straight forward and could be made on our Trak 3-axis CNCs using the Solidworks file provided by the customer, uploaded into our Mastercam software. One of the molds had a very unusual shape in the body of the mold that could not be made using our existing software, and needed 3D modeling and surfacing software, which we did not have. We reached out to the Mastercam salesperson, who offered us a proposal for a software upgrade to enable this additional capability.

This is where the story gets interesting …

The expenditure for the software upgrade was more expensive than we had anticipated, which also required that we send personnel for training to a regional training facility. In addition to cost and commitment for personnel, we also could not meet the requested timeline for building the molds for the customer. We had to develop an alternative plan, so we could take advantage of this new opportunity.

On the Right Trak

One of the reasons we chose to buy Trak machines was because our machinist has used this equipment for years and is very familiar with their programming and operation. In addition, Trak is supported locally with a sales office in Massachusetts, and with very experienced sales and sales engineering personnel. They also build a quality machine that is priced right for our size operation, with a lot of modern features, such as touch screen, etc. We picked up the phone and called our sales representative and asked him for advice on how to solve this problem.

The salesperson indicated that he had a great relationship with Mastercam, but also had a long-standing relationship with Hawk Ridge Systems, which sells CAMWorks, a competitor of Mastercam.

They put us in touch with the other salesperson, who came to our facility the following day, and brought an engineer with him to review our project to ensure they could provide a solution for our needs. The result was a proposal for the software upgrade we needed that was less money, gave us increased programming capabilities, was installed in a few days and we were able to meet the customer delivery requirements. Since we did not have trained personnel to do the surfacing requirement, the engineer agreed to support our timeline by providing the programming at no charge, working with our machinist as part of training. Obviously, we will still need some formal training after the fact, to be able to utilize the software for future jobs, but that would not have helped us in this situation.

We built the three molds, and delivered them for our customer, and they appear to be very satisfied with the quality, pricing, and delivery. We now have the capability to pursue additional molds for our other existing customers, which will help us achieve additional revenue growth in 2023.

The Moral of the Story

The moral of this story is: Ideally you want to have a proactive, well-planned project-based NPI initiative to stay current in your market. There are times when a customer requirement will surface that gives you an opportunity to add capabilities for them, that can then be offered to other customers in your customer base. The timeline for these opportunities may be more time sensitive, and then there is the cost … with a little creativity and good supplier support, we were able to acquire these new skills on time and with a reasonable cost basis. Bring on the next opportunity …

Check in to read our next blog to find out the larger scope of what this agile mindset means to prospects and customers. This ability to be flexible, shift, and integrate new/better production opportunities benefits all stakeholders. We’re happy to talk with you about your NPI needs. Contact us now to begin the discussion.