Why it Needs to be a Partnership When DFM Design Efforts Are on the Table It is imperative that you...

Why Consider Design for Manufacturability?

Where and How to Begin Your DFM Initiative

When is it time for a new design for your product? A loaded question, to say the least. We want to conquer this subject for you, because we know how multi-faceted it is to plan and implement new product design. (We’ve been doing this for many decades.) This blog begins a series dedicated to DFM initiatives—the other subjects we will cover are noted at the end of this post.

Why Consider DFM

The reasons for creating a new design for your product don’t exist in a vacuum and it’s common that there are multiple variables occurring simultaneously to motivate a design change. Here’s a quick rundown of a few that you might be facing:

- Your product was designed so long ago, and there have been many advances in manufacturing practices that will allow for easier and less expensive ways to produce the products.

- Sales are slowly declining, and the competition is starting to pull away some of your long-term customers.

- There are increasingly more part shortages due to obsolescence, and engineering is spending much more time resourcing alternative components.

- Marketing is looking for “something new, more cutting edge” to help them continue to sell the products.

- You have had declining gross margins due to cost increases in raw material and labor costs, and are not able to pass them on to your customers.

- Customer demands are shifting—whether from advances in their markets or end-user needs—and you must meet their new requirements.

Where to Start

It can be a daunting task to “start new,” so let’s break down some of this. You might be asking yourself: Okay, so I am suffering under the weight of one of these scenarios, what can I do to get started?

Here’s the first question you need to consider: do you have the internal resources and available technical expertise to support the DFM effort? If the answer is NO or MAYBE, then you should consider pulling in external expertise to supplement your efforts.

Which brings us to the next logical one: how do you decide what type of expertise to use? First of all, whoever you engage in this effort should have prior experience and a desire to support the DFM effort, because it requires them to commit time, effort, and risk—working closely and collaboratively with your team—to explore all the possible design iterations. Along with that, they must be willing and able to work on developing alternative configurations, possibly exploring new technologies outside of the existing supplier base, and then documenting, testing, and tooling for the new build. There may also be a need for additional training of existing manufacturing personnel if the complexity of the new product exceeds the current skill level.

There are several factors to be taken into account regarding the selection of outside resources. Here are some to consider:

- Is the make-up of your current product, and the amount of specific content within the product, based on industry specialties?

- Does your potential redesign include PCBs or other electronic controls?

- Are there various mechanical components, or sheet metal, or molded parts?

- Will there be any requirements for the development of software or firmware?

- Are there any industry-specific regulatory requirements that must be met?

- Do you have a clear idea on the needs and expectations of your customers, and what impacts the design changes will have on marketing?

For all these reasons, it is recommended that you assemble a team of people—from inside your organization—to be complemented by outside resources to augment your technical capabilities, and who have access to suppliers with specific capabilities beyond your current supplier base.

Teamwork

Now you have your team assembled: where do you begin?

Step 1

This first meeting is for widening your vision, encouraging imagination—and involves conducting a SWOT Analysis. SWOT is an acronym for strengths, weaknesses, opportunities, and threats. This consists of conducting a round-table discussion, analyzing your current product, and trying to determine what you need to do to make it better, cheaper, faster, easier to build, possibly with more desirable features than your current offering. Obviously, someone from sales or marketing needs to be in this meeting, along with engineering, manufacturing, senior management, and possibly, finance.

The use of a whiteboard or easel and paper to record the discussion is critical. No answer is too stupid to record. Someone should be designated to summarize these notes and distribute them to the team. The second meeting of the team is intended to consider all the ideas generated in the first meeting and to cull down the list to a manageable set of action items that the majority of the team agrees are appropriate, based on the original discussion. This list will assign tasks to members of the team to pursue any or all of the following tasks:

- Research by gathering more data

- Find a supplier who can help in a specific area of expertise

- Interview customers for more specific feedback

- Request funding for possible new equipment

- Find a raw material that will meet the new specifications

- Reach out to the regulatory body for a more detailed explanation on meeting an important industry requirement

As stated, the actions coming out of this meeting could require some or all of this discovery, but this “homework” must be done before the team can decide on a specific plan of action that will have a high level of probability for success.

Step 2

This second meeting is for narrowing the team’s focus, and encourages research and collaboration. Assuming that the work that follows leads to a decision to actually redesign the product, the real work will begin. At this point, you need a team leader who can outline a specific timeline for the project, taking into consideration, time, cost, available resources, and other variables that are occurring simultaneously with in the organization.

There are many tools available for this phase of the project. One popular tool is the 6-phase Stage-Gate project management approach. Anyone in development understands the stages intrinsic in development: discovery, scope, business viability, development, test and validate, and launch. Established project management tools help to define the phases, with criteria at each gate (that act as checkpoints), promoting transparent communication, and avoiding risk—all to streamline the efficiency, viability, and the ultimate success of your launch. You should consider using this type of tool to manage the actions of this team, and to ensure it is not subject to scope creep, or other diversions that can cause an effort to fail.

Where Am I Coming From?

Prior to coming to Diversified Machining, I was fortunate to run a very successful mid-sized cable assembly manufacturing operation for over four decades. In that time, my team and I learned invaluable lessons about building relationships and working with customer, vendors, and suppliers we came to trust and depend on. In fact, I sold Fourstar and became business partners with a former manufacturing partner—the new Diversified Machining—that’s how deeply our relationships ran! We worked so closely with people in all sectors, that we gained a depth of first-hand knowledge on a variety of subjects, everything from PC board design to outsourcing domestically and internationally.

As you can see, selection of the appropriate outside resource(s) is critical. If you are choosing a manufacturing partner, you want to ensure that they have an established, reliable, stable ecosystem of manufacturing and supply chain partners that can provide support on all levels with DFM and NPI initiatives. Years in the business working on DFM and NPI projects have taught me how valuable these relationships are and how necessary they are to fill in any gaps manufacturers, suppliers, and customers might have—whether for consultative, production, and secondary manufacturing, or finishing work. Keep in mind that we, as the partner spearheading the DFM, also own much of the risk, so we are meticulous in our approach and process, along with who we select to partner with when we outsource to provide DFM-related services and products to our customer (when needed). Here are some of the value-added relationships we bring into the mix when completing DFM and NPI projects for customers:

- Electronics: Heilind Electronics, Sager Electronics, TTI, Inc., Walker Industrial, Anixter Wire and Cable, IMS

- 3D printing and mold makers: Empire Group, Inc.

- Plating and finishing: Coating Systems Inc.

- Sheet metal: Metal Works, Inc., Fabco Manufacturing

- Cable assemblies and box build, domestic and international: Agility Tech

- Internet of Things software development: Agility Tech

- Electrical design: Power Guide

- PCB assembly: Worthington Assembly, Inc.

As promised, we will continue this discussion in a series of blogs, some of which will explore the following topics deeper:

- IDing the need to do a DFM

- How to set up a team to start the process

- Specifics on how to run the team

- Timing and implementation

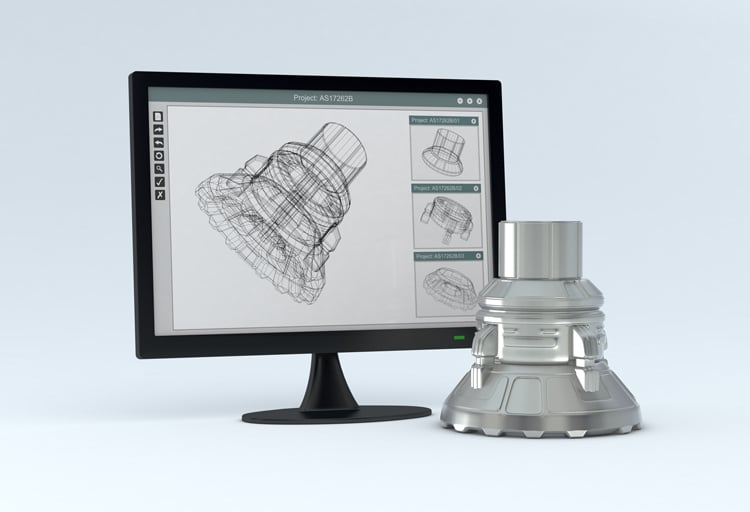

- If you have machine parts: metal and plating

- Cable assembly

- Software development

- Handling change-orders

- Product testing

- Regulatory approvals

Excited for DFM

Our team loves the excitement and challenge of DFM, and we bring decades of experience guiding DFM and NPI projects—along with our vast network of trusted industry contacts. We know who works well with us and how to manage the stage gates of DFM. We welcome new customers to put their trust in us as contract manufacturing partners for your machined parts. We provide low- to mid-volume, assembly, lathe, and manual work. Allow our 80-plus years of collective experience in prototype and production machining, along with expertise in efficient new product development and introduction and design for manufacturability work for you. We’d love to hear from you. Contact us now to get started.